Profile

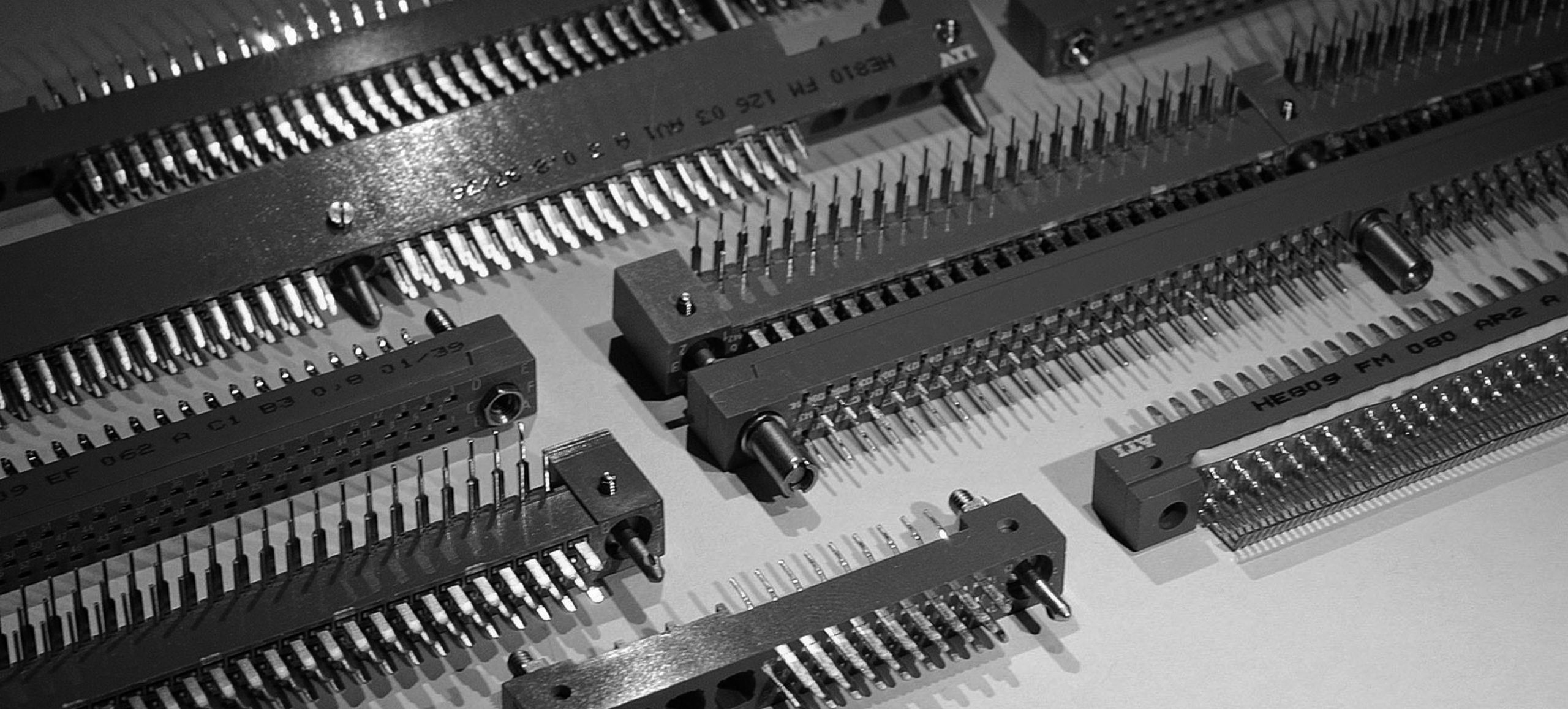

ATI INTERCO designs, manufactures and commercialises complete connectivity solutions, a range of connectors for printed circuits and interfaces, custom connectors, backshells and a large range of cabling components and circular or rectangular connectors accessories.

From the first design phase we use validated, tested technologies combined in innovative and pertinent ways to ensure the reliability, security and ergonomics of our customers’ harsh environment electrical systems.

ATI-INTERCO produces connectors for printed circuits (board to board connectors), modular miniature connectors (mixed layout connectors with signal, coaxial and power contacts), RF connectors, filtered and shielded connectors…. Our non-catalogue products are designed and manufactured to stringent customer specifications (custom design connectors). It also manufactures backshells for circular and rectangular connectors in standard sizes and to individual customer specifications, junction boxes, a vast range of cabling components, as well as circular connectors and high performance interconnection systems for custom applications.

ATI-INTERCO also develops complete sub-systems to ensure system compatibility and interoperability (military connectors, avionics connectors).

Our principal markets are civil and military avionics and space, defence, (missiles, marine, ground based & communications), rail transport and signalling, and all industries using electrical connectors in harsh environments like nuclear energy.

Our commitment is dedicated to our customers’ needs, from Design to Satisfaction.

History

Professional organizations

ATI-INTERCO are members of some professional organizations such as :

GIFAS

French Aerospace Industries Association

ASTECH Paris Région Cluster

Aerospace competitiveness cluster

FIF

French Railway Industry Association

Values

ATI Electronique and Interconnexions

ATI Electronique and Interconnexions joined forces in 2009 in order to provide complete connectivity solutions. Since January 1st 2012, these two companies have a new identity and they are called ATI-INTERCO.

ATI-INTERCO, a human size company…

Thanks to a qualified an experienced staff of 106 employees trained in the most modern technologies in the field, and internal facilities for design (computer aided design, prototyping and testing) and production (computerised machine tools, moulding, assembly and testing), the two sister companies are innovative and flexible.

Our principal markets

Our principal markets are civil aviation, military aviation, space, defence, (missiles, marine, ground based & communications), rail transport and signalling, and all industries using electrical connectors in harsh environments.

Research & Development

A technical expertise…

ATI-INTERCO possesses a broad and highly competitive technical expertise thanks to a policy of continual investment.

Significant resources are assigned to research and development, there by permitting us to propose innovant and original interconnection solutions to our customers.

Laboratory

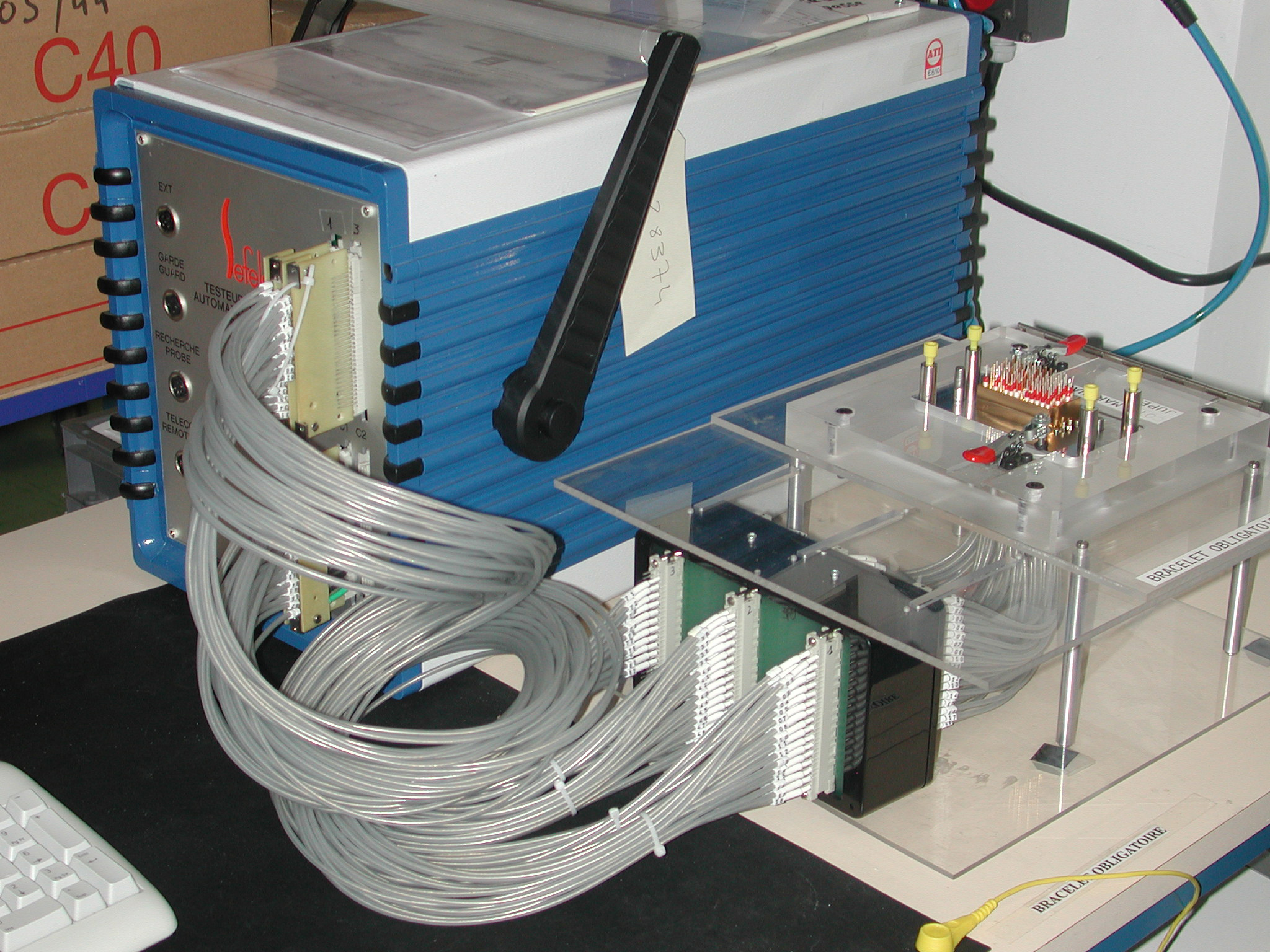

Electronic and mechanical laboratory

Our prototypes are created in our laboratories by experienced technicians.

Testing laboratory

All our products undergo rigorous electrical, mechanical and climatic testing.

Production

Machining

The mechanical workshop incorporates CNC machine tools and presses for thermoplastics, thermosets and elastomers. The workshop is fully supported by specialised maintenance facilities.

Plastic injection

Assembly

Assembly, waterproofing, compounding, cutting, stripping, cabling, soldering and welding are carried out in our workshops.

Labeling

All our products are labelled by inkjet, laser or etching.

Applying the REACH regulations , n°1907/2006 (18 décembre 2006):<br />

ATI-INTERCO respect the european directive REACH.

The status of our companies with respect to the directive is the following: non manufacturers of “substances”, non manufacturers of “preparations”, “downstream users” and “producers of articles”. We are “downstream users” and “producers of articles” where the substances present in our articles are not destined to be disposed of in “reasonably foreseeable usage conditions” and are considered as such in the case of normal “industrial use”. As such, we are not obliged to pre-register the substances used in our preparations. Also, the substances listed in the PDSL (Priority Declarable Substances List) present in our articles represent a usage inferior to 1 tonne per year. We have turned to our suppliers and requested details of their actions in respect to REACH. Today we use the last candidate list published twice a year by the ECHA.

The case of cadmium chromate (cadmium + chrome VI) is linked to the W class of standards for connectors (Conductive coating and 500 hours in saline mist) and linked to the specifications of certain customers, who are obliged where possible, to specify a substitute.

Applying the directive 2002/95/CE (RoHS):<br />

The position of ATI-INTERCO consists of proposing all of our product ranges in a version “RoHS”. At ATI-INTERCO, we have chosen to follow the demands of the market. We also keep available the current versions of our products notably for the market segments where no technical modification to the product can be tolerated throughout its service life.

For most of our products, conforming to the directive RoHS consist of removing the lead from our surface treatments. It should be noted that many of our pieces treated with a tin-lead (SnPb) 90/10 coating are also available with gold (Au) coating. Since the 1st January 2006 all our catalogue is available in lead-free versions. All lead-free products have a dedicated reference and are marked as such. All our new products developed since the 1st January 2005 are RoHS compliant.